FlexMix PRO is a process control system designed specifically to feed mills, pet feed plants and premix plants. Many years of experience have been put into this system, providing for quick start-up and intuitive operation. It is quick and easy to adjust any modifications of the plant to the system - it is not necessary to have an expensive PLC technician compile software. As standard, FlexMix PRO features many registrations and calculations, providing the user with a complete overview of economic and nutritional matters in the feed production. FlexMix PRO features very sophisticated techniques for optimizing the production and for running the plant unstaffed when possible. At the same time, the operation of the system is very simple and intuitive.

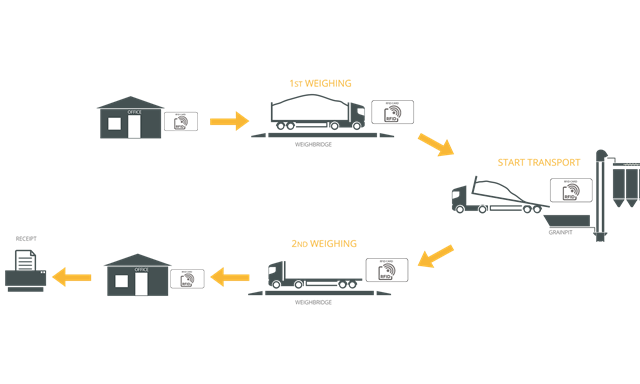

FlexMix PRO is fully user configurable and built up from a number of modular blocks to control the requested fields of production. This includes the intake of raw materials, grinding, mixing, and loading. Control of pellet press/extruder is integrated into the FlexMix PRO by third-party systems. The system is fully scalable and configurable to all feed mills, from small farm plants to large industrial plants. It is easy to modify the system from controlling one field of the production to comprise any extensions if the need arises. Many modifications can even be made while the plant is operating.

Solid and reliable

FlexMix Pro software is now well tested and has now shown its worth with many installations worldwide. FlexMix PRO is a system designed specifically to control of feed mills. Many years of experience have been put into this system, providing for quick start-up and intuitive operation. It is quick and easy to adjust the system to any modifications of the plant. In many cases, adjustments can be made online via remote support.

FlexMix PRO features a safe user control preventing unauthorized admission.

Tiếng Anh

Tiếng Anh

Người Đan Mạch

Người Đan Mạch

Người Pháp

Người Pháp

Tiếng Thụy Điển

Tiếng Thụy Điển

Tiếng Việt

Tiếng Việt

Người Tây Ban Nha

Người Tây Ban Nha

Tiếng Đức

Tiếng Đức

Tiếng Anh

Tiếng Anh