Extrusion Aqua Feed Mill

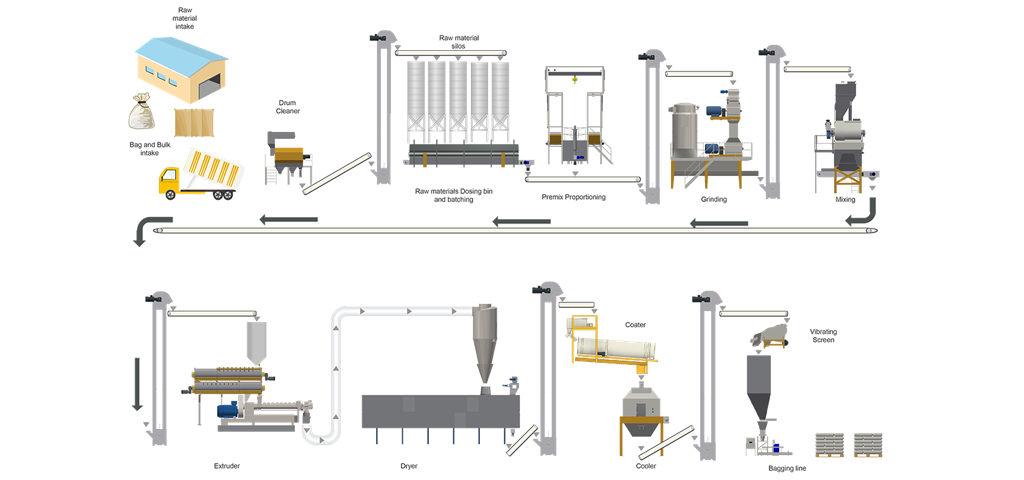

SKIOLD Extrusion aqua feed mill has solutions that are pre-engineered to a very high level of details. The detailed pre-engineering is setting a new standard for aqua feed plants in the low and mid-range size of a capacity from 5 to 10 TPH for floating fish feed. This solution contains all the technology needed in the process, from the intake all the way through to the bagging of the ready aqua feed. The solution is designed in a modular system of well proven equipment of recognized brands but still has a flexibility, so it can be customized to meet the requirements of our customers.

The TTM (Time To Market) of the fish feed products is shortened once the investor has decided to build a new Aqua Feed Mill because of the very detailed pre-engineering that rapidly can be put in the process of planning and activating an Skiold Aqua Feed Mill project. The pre-engineering will help to speed the process of making decisions in terms of the final design of the plant. This can also lead to a smoother authority approval process, discussions and agreements with a construction company for civils and buildings and an agreement with a subcontractor for the installation.

The concept allows our customers to source the total project at SKIOLD, avoiding single sourcing of equipment and the engineering of putting a system together. As a turnkey supplier Skiold takes the responsibility of the engineering, sourcing of equipment, supervision of installation and commission of the plant.

Safe to operate with traceability and biosecurity in focus

SKIOLD works to improve the quality and safety of feed by using efficient and innovative technologies throughout the process resulting in higher profitability in the entire supply chain.

Our Aqua Feed Mill plants are designed to minimize number of necessary operators. Also, process overview and a safe working environment has been taken into account when designing the plant. Biosecurity is increasing in importance and the automated flow of raw materials through the plant, thermal processing and storage of the finished feed have been logically planned so that all is kept separate, eliminating contamination and ensuring a high level of biosecurity.

The feed extrusion plants are controlled and monitored from the SKIOLD FlexMix Pro control system. This system is easy to operate, production is continuous even during the change of formula and offers you a complete production overview. Components are traceable from supplier to customer in the all-in-one software package.

Tiếng Anh

Tiếng Anh

Người Đan Mạch

Người Đan Mạch

Người Pháp

Người Pháp

Tiếng Thụy Điển

Tiếng Thụy Điển

Tiếng Việt

Tiếng Việt

Người Tây Ban Nha

Người Tây Ban Nha

Tiếng Đức

Tiếng Đức

Tiếng Anh

Tiếng Anh